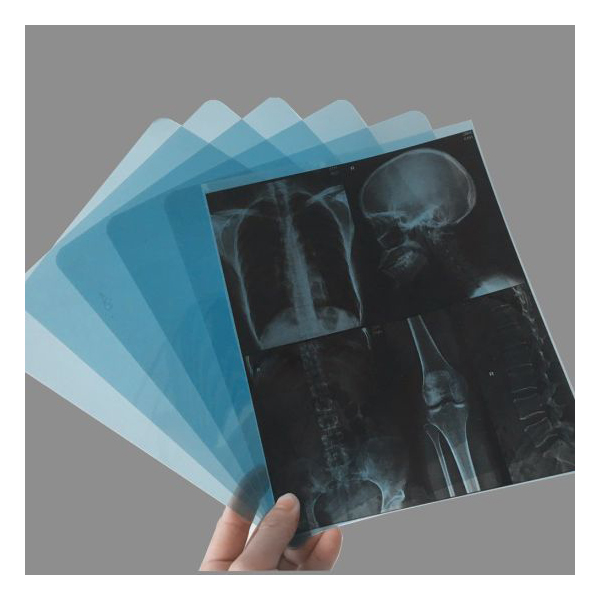

Dry Film for Dicom Printers

MPIN: MP41105

Sign in to view pricePremier quality and throughput built on experienceSeveral years of experience with Direct Digital printing into designing the Dry Printer imager in order to produce the very highest diagnostic quality greyscale hardcopies. To support these topoftheline imager a special medium DRY film was developed. It is capable of coping with the higher throughput of the advanced imagers.

Ask for Quote

Dry Film for Dicom Printers

Benefits

Premier quality and throughput built on experienceSeveral years of experience with Direct Digital printing into designing the Dry Printer imager in order to produce the very highest diagnostic quality greyscale hardcopies. To support these topoftheline imager a special medium DRY film was developed. It is capable of coping with the higher throughput of the advanced imagers. Stateof the art Direct Digital dry imaging technology produces grayscale hardcopies with high Dmax and contrast. It gives the same clear highquality results as wet laser film but offers all the advantages of dry technology no wet processing no darkroom and no chemicals.Ecological technology in an easytouseThe Direct Digital dry imaging technology ensures easy and convenient use. The heatsensitive characteristics DRY film make daylight loading effortless and as simple as inserting a CD into your PC. With no wet processing or darkroom required there is no need for cleaning products timeconsuming adjustments or chemical disposal. Image processing is more efficient and costeffective. The DRY film packaging is fully recyclable and combined with the elimination of processing chemicals provides a more environmentally friendly solution.Consistently clear and sharp imagesDRY film is built on a 168mthick PET base coated with silver salts and covered with a protective top layer for resistance to scratches and moisture. The PET base has rounded corners to allow the medium to be handled in the same way as regular Xray film. The silverbased imaging layer is heatsensitive rather than lightsensitive guaranteeing low fog and high contrast combined with excellent image stability.

Specification

USAGEDimensions (W x D x H)For medical printing of greyscale images on 168m PETChoice of blue and clear baseMaximum optical density 3.1Fully recyclable packagingDaylight loading Dedicated Imagers20 x 25 cm (8 x 10 inch)25 x 30 cm (10 x 12 inch)28 x 35 cm (11 x 14 inch)35 x 43 cm (14 x 17 inch) Storage 100 sheets per box Shelf life 24 months after manufacturing date Storage before useTemperature between 4 to 25 CThe recommended humidity control for DRYSTAR films is between 30 and 60% Storage after printingArchiving facility complies with ANSI IT 9.11 and IT 9.19 extended termRecommendations & Carriage to avoid image lossAvoid storage for a long period of timeAvoid dry media on view boxes for a longAvoid exposure to excessive high temperatures and intense light store the images in the original packaging or other appropriate protective film envelopes at max. 25 C.

Shipping Policy

Orders made at Medpick are initiated and processed for shipment upon receipt of request from the customer. Please note that our Shipping Services (Fee, Transportation, Loss or Damage of any shipment, etc.) are in accordance with the Seller\'s terms of Shipment.

Refund Policy

Please refer to Medpick Return Policy.

Cancellation / Return / Exchange Policy

Please refer to Medpick Return Policy.

REGISTER

REGISTER

SIGN IN

SIGN IN